The local 3D printing scene

Egypt’s 3D printing scene: Young, but the potential for disruption is there. A nascent technology in Egypt and the world, 3D printing has the potential to revolutionize industries like healthcare, automotives, aerospace and construction with its highly customizable, low-cost solutions. With the global market on course to triple in value over the next five years, the manufacturing technique is increasingly finding a foothold in Egypt, with fabrication labs appearing on university campuses and everyone from business incubators and hackerspaces to medtech startups eyeing international markets with their technology.

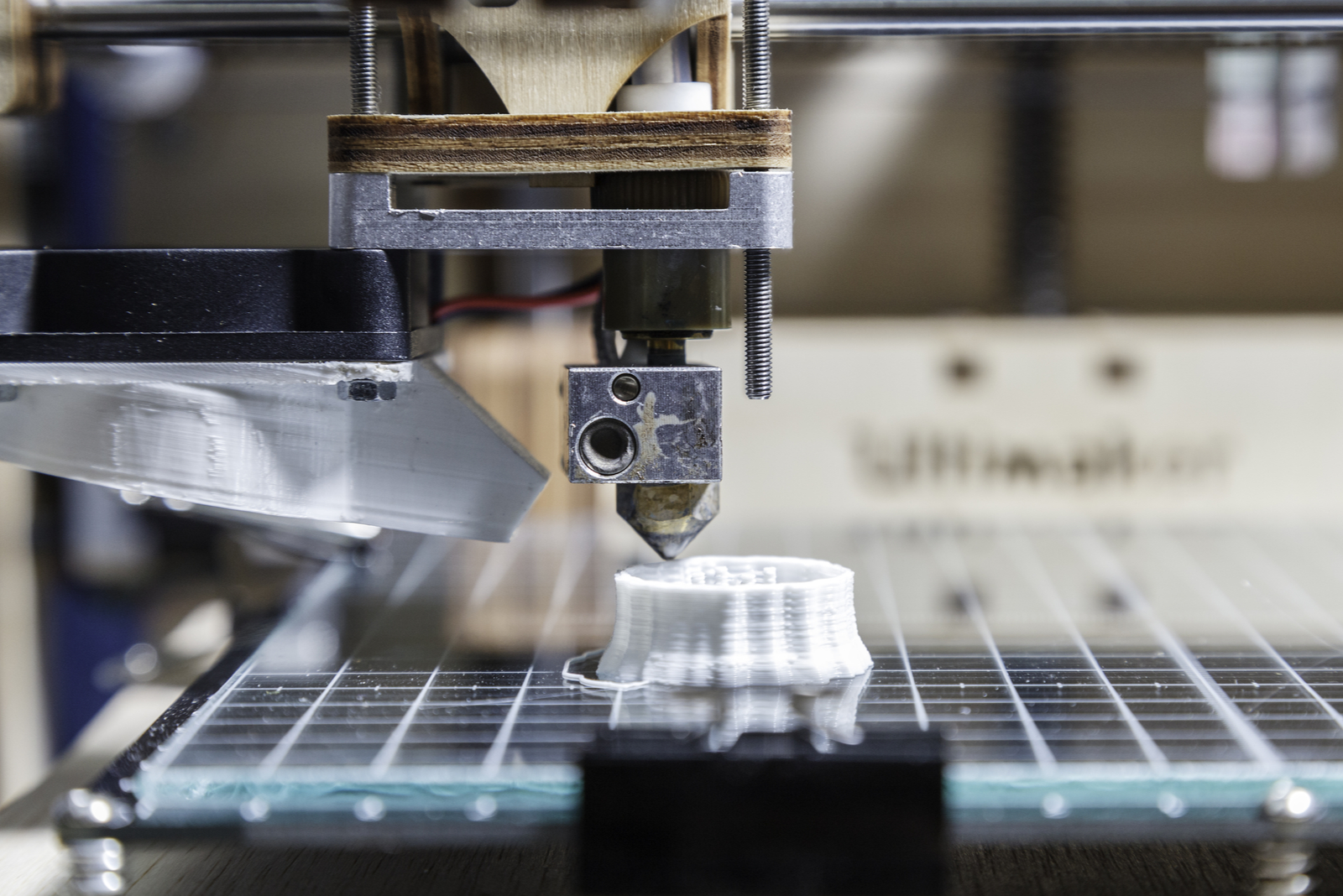

For the newbies: 3D printing is a form of additive manufacturing, which allows for the construction of 3D objects through computer-aided design (CAD). Objects are printed on 3D printers, which range from homemade DIY machines that can print small objects for, say, medical or engineering purposes, to 3m+ tall machines that are used to build houses.

Right, but how does it work? Additive manufacturing, unlike traditional manufacturing, works by adding layers rather than removing them to make a product — think of it as the difference between carving a sculpture out of wood (traditional manufacturing) and frosting a cake (additive manufacturing). This layering process eliminates waste and allows for the manufacturing of complex objects that would be much more difficult (and costly) to produce using conventional methods. In addition to being used for rapid prototyping, additive manufacturing allows designers to create spare parts at a lower cost.

It is highly customizable and decentralized, making it super versatile: The technology has come a long way since its inception in the 1980s, and today anyone with access to a fabrication lab and an internet connection can 3D-print. Open-access blueprints are easy to download online, or if you know your way around 3D modelling software, you can design your own creation. This makes 3D printing one of the most versatile manufacturing techniques — and one that is completely decentralized.

One of the first fabrication labs to introduce the technology in Egypt was Fab Lab Egypt (FLE), which launched back in 2012. A member of MIT’s global Fab Lab network, FLE has a network of fabrication labs and makerspaces across Egypt. Now run by San3a Tech — a company established by FLE’s founders in 2016 — the organization has worked with a number of multinationals including Intel, Orange, and Dell on digitally-fabricated products.

Another key player in Egypt’s 3D printing space: Creatables. Officially launched in 2018, the Mokattam-based engineering company was incubated by the makerspace Cairo Hackerspace and specializes in digital fabrication, offering CAD design, 3D scanning, and a 3D printing farm. The engineering, architecture, art, film and advertising sectors have all benefited from the technology, Hady Mohamed, one of the co-founders of Creatables, tells Enterprise.

Universities and business incubators are the perfect home for fab labs, so it’s no surprise that Heliopolis University’s (HU) Center for Entrepreneurship and Innovation hosts a small fabrication lab that they are now expanding in collaboration with San3a Tech. The lab is open to businesses and university students to create prototypes and develop models, Karim Mallawany, executive director of the center, tells us. So far, it has been used primarily for R&D purposes, but Mallawany hopes that adding a 3D scanner to the lab will enable the design of more sophisticated products.

It’s making ripples in health: At the height of the covid pandemic, 3D printing was used to print test swabs, protective gear, medical devices and respirator parts — but this is just skimming the surface of how the technology can revolutionize healthcare. Today, doctors are testing how 3D printing can be used in regenerative therapies to print small body parts and possibly even organs, and it is already being used for prosthetics and to prepare doctors for complex surgeries. Giza Systems’ digital fabrication lab, part of Giza Systems Education Foundation (GSEF), is working to design and print prosthetics, customized wheelchairs, and even bionic eye devices to assist people with disabilities.

Egypt’s dental industry is embracing the technology: Dental tech startup Mogassam has been in the business of making 3D printers for the dental industry for the past four years, selling 120 printers in that time, with plans to expand sales into the US next year. Cofounder Ahmed Adel tells us that the dental industry has been quick to embrace the technology, with dentists turning from “craftsmen to designers,” as they adapt to print everything from permanent crowns to transparent braces, dentures, veneers and surgical guides on in-house 3D printers. Adel, an engineer, is optimistic that Egypt can make strides in 3D printing for the health sector. “The field is new in the whole world, so the gap between Egypt and the rest of the world still isn’t that big.”

It’s also making an impact in manufacturing: Factories in Egypt are now using 3D printing to replace gears or spare parts on production lines, Mohamed says. In other countries, such as the US, the technology is routinely used for manufacturing and prototyping in industries including aerospace and automotives.

Ready to print the new capital? Not quite, but the potential is there: Imagine a house, built like a soft-cone ice cream, swirl upon swirl piling up to make a dwelling for a family within 24 hours. This is now possible with 3D printing. Some companies are even using it to build whole neighborhoods, while others are using it to mitigate homelessness by providing low-cost social housing and disaster relief shelters. With no long-term proof of concept, investors are still wary of the sustainability of 3D printed houses, but some companies are betting on automating the construction process because of its potential to cut labor costs, produce less emissions and turn around a final product faster.

Want more?